- Europe

- FANUC Europe

- Albania

- Andorra

- Austria

- Belgium

- Bosnia and Herzegowina

- Bulgaria

- Croatia

- Cyprus

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Iceland

- Ireland

- Israel

- Italy

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Moldova

- Montenegro

- Netherlands

- North Macedonia

- Norway

- Poland

- Portugal

- Romania

- San Marino

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

- United Kingdom

- Vatican

- Americas

- USA

- Africa

- Algeria

- Egypt

- Morocco

- Tunisia

- Asia

- Armenia

- Azerbaijan

- Georgia

- Kazakhstan

- Kyrgyzstan

- Tajikstan

- Turkmenistan

- Uzbekistan

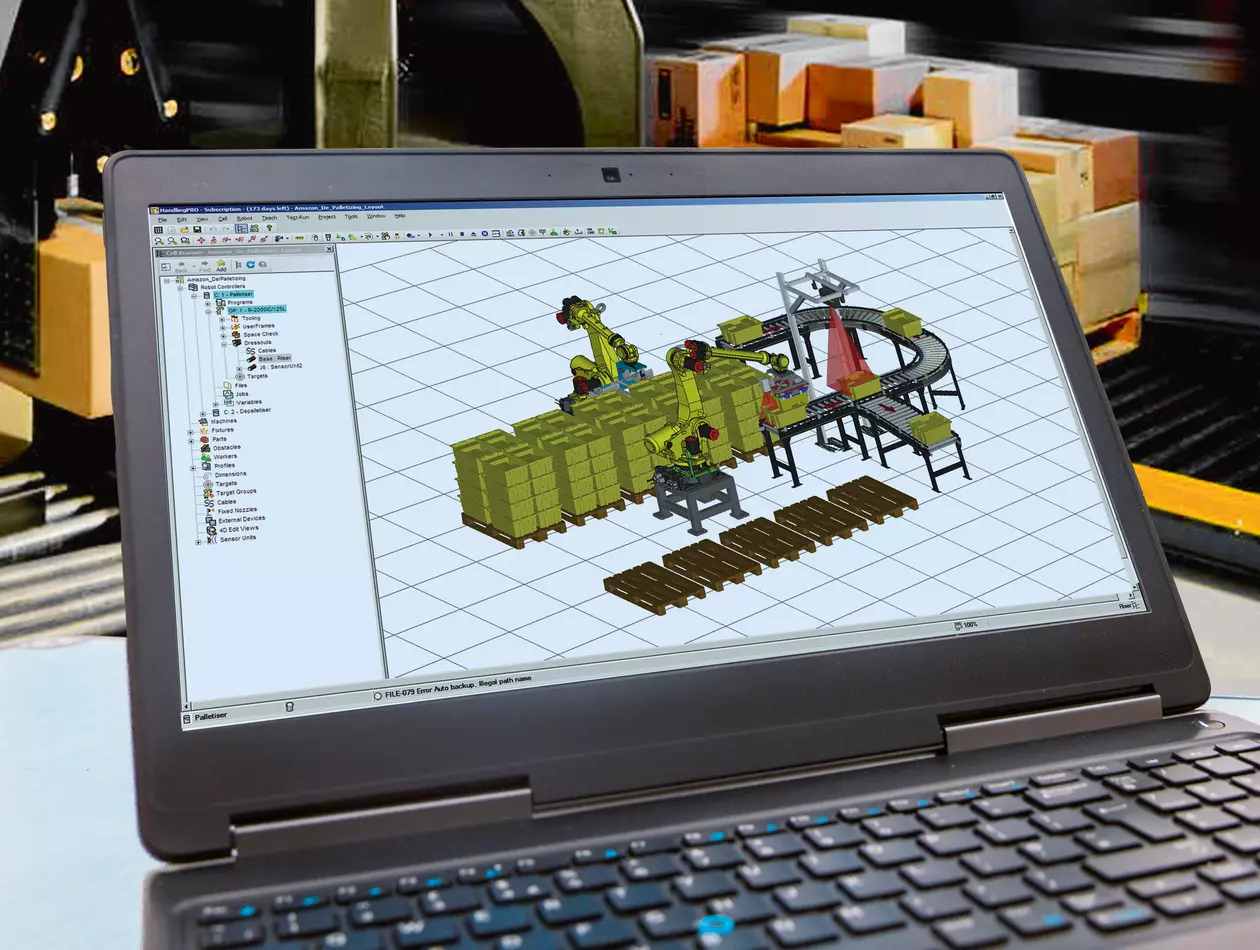

R-1000𝑖A/80H

The R-1000𝑖A/80H is a robot designed for efficient and space-saving palletising. Its slim design and minimal footprint make it a perfect fit for space-constrained cells. Renowned for its fast performance and robust 5th axis, this robot excels in palletising applications that demand high throughput and unwavering reliability. Ideal for operations looking to maximise efficiency without sacrificing space, the R-1000𝑖A/80H stands as a testament to precision engineering and practical design.

Robot Payload

80 kg

Robot Reach

2230 mm

Axes

5

Get Inspired

Perfect Fit for Your Application

Palletising

Automating your palletising process can boost both the safety and efficiency of your operations. With a wide range of options to choose from, you’ll find the perfect fit for various sizes, payloads, cycle times, and precision needs, all while ensuring your products are handled with the utmost care.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

FANUC’s advanced robotics: optimising aerospace manufacturing processes.

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

Robotics & Automation for the Medical Industry

Enhancing medical industry efficiency through robotics and automation!

Warehousing, Logistics, Post & Parcel

FANUC's wide offer of warehouse robots fit the needs of anyone looking to apply automation to their warehouse, distribution center, fulfillment center, and more.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT